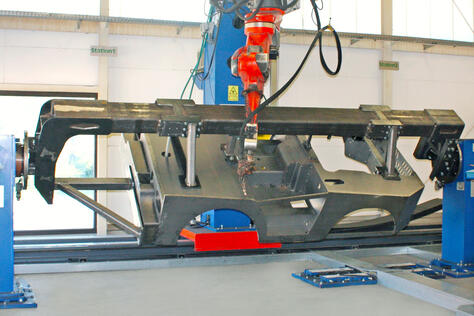

Cloos welding robot: Automated welding

The CNC-controlled Cloos robot welding machine offers maximum flexibility in automated welding. Thanks to two rotating/swivel work-piece positioners arranged side by side, the machine can be loaded and unloaded simultaneously. By uniting the two work-piece positioners, structural components with a length of up to 7 m can be welded.

A high seam volume can be generated by using a tandem welding torch. A high welding speed is also possible by using the tandem welding torch.

An on-line follow-up of the welding seam is possible with a laser sensor attached to the welding torch. This guarantees a clean torch guidance at the work-piece and so ensures high seam quality. Furthermore, the welding torch can be positioned very precisely on the work-piece by the laser sensor.

Cloos welding robot performance data

Machine:

CLOOS QIROX C

Welding head:

One and two wire welding head

Procedure:

MIG-MAG

Working area:

Two stations: 3,200 x 1,600 x 1,600mm.

One station: 7,000 x 1,600 x 1,600mm

(larger dimensions on request)

Load:

max. 4,000kg

Advantages of Cloos welding robot

- High process safety and automation by CNC-control and laser sensor

- Optimum seam course by on-line follow-up

- Simultaneous loading and unloading

- High welding speeds

- Economical welding also of big components

- High quality of welding seams

This might also be of interest to you

-

Assembly

Assembly of mechatronic systems as part of the sheet metal production – from prototype to line production.